- Home

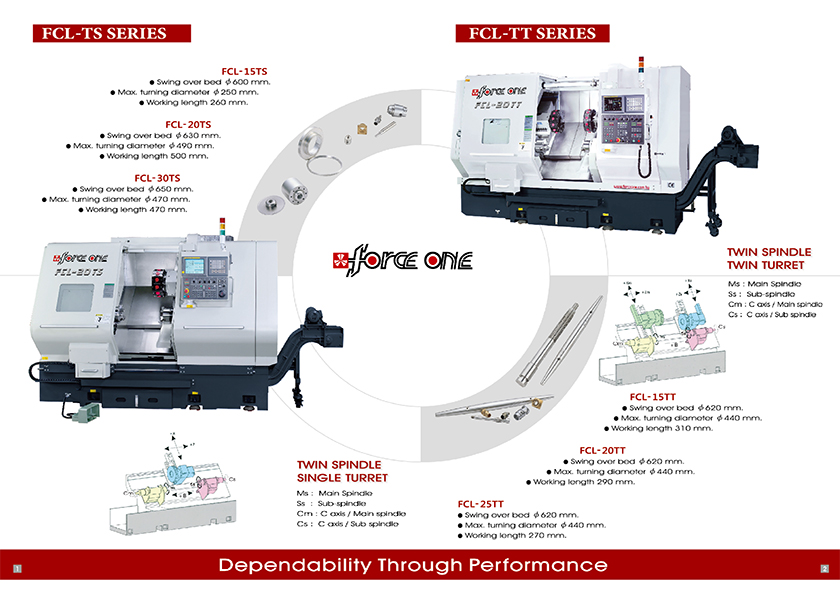

- Turn Mill center / Twin spindle, Twin turret

- FCL - 25 TT / Turn Mill center / Twin spindle, Twin turret

FCL - 25 TT / Turn Mill center / Twin spindle, Twin turret

RUGGEDLY AND PRECISELY CONSTRUCTED THROUGHOUT (linear guide way)

STANDARD ACCESSORIES OPTIONAL ACCESSORIES

SPECIFICATION

| Swing over bed | Ø 620 mm ( 24.41” ) |

|---|---|

| Max turning diameter | Ø 440 mm ( 17.32” ) |

| Working length | 270 mm ( 10.62” ) |

| Spindle nose | Main : A2 - 6 Sub : A2 - 6 |

| Bar capacity | Ø 65 mm ( 2.5” ) Ø 52 mm ( 2” ) |

| Hydraulic chuck | Ø 254 mm ( 10” ) Ø 210 mm ( 8” ) |

| X1、 X2 axis travel | 245 mm ( 9.64” ) |

| Z1、 Z2 axis travel | 342 mm ( 13.46” ) |

| B axis travel | 470 mm ( 18.5” ) |

Features

- The overall structure utilizes Meehanite casting process, enhanced with annealing to reduce internal stress, ensuring high rigidity and stability.

- It's equipped with a servo turret and a VDI longitudinal tool disc, enabling efficient processing of workpieces both front and rear, and facilitating quick tool changes.

- The main and sub spindles can perform synchronous machining, allowing for the completion of workpieces in one operation.

- The spindle, constructed in a barrel-type design, uses P4 bearings to provide high axial thrust, radial stability, and precision, enabling cutting on larger lathes.

FORCE ONE MACHINERY

FORCE ONE Machinery has over 20 years experience, and the company’s Chief Engineer of CNC has 20 years background.

E - catalogs